Blogs

-

Posted: May 02, 2024Read more »

Exploring 3D Printing: Resin vs. Filament

When it comes to 3D printing, two primary technologies dominate the market: resin-based printing and filament-based printing. Each method has its unique strengths and weaknesses, catering to unique needs and preferences. In this blog post, we'll delve into the pros and cons of both resin and filament printing, helping you understand which option might be best suited for your projects.

Resin Printing: Precision and Speed

Resin printing, exemplified by Phrozen Resins, is renowned for its exceptional precision and speed. Using liquid resin cured by UV light, this method produces highly detailed prints with smooth surfaces. The curing process occurs layer by layer, resulting in faster printing times compared to traditional filament printers. Additionally, resin prints require minimal post-processing, making them ideal for intricate designs and rapid

Posted: April 19, 2024Read more »WASP Showcases Cutting-Edge Innovations at Exposanità 2024

Discover the Future of Healthcare 3D Printing!

Introducing the WASP 4070 FX: Precision Redefined

Step into the realm of ultra-precise filament printing with the WASP 4070 FX. Engineered to perfection, this industrial-grade 3D printer is designed for flexible materials such as TPU, TPE, and PP—materials synonymous with medical innovation.

Experience High-Definition Printing with the WASP 60100 HDP

Prepare to be captivated by the WASP 60100 HDP, a large-format 3D printer capable of rendering intricate designs with unparalleled clarity. Whether it's flexible or non-flexible materials, this cutting-edge device delivers superior results, setting new standards in medical-grade 3D printing.

Witness the Future Unfold

Experience a showcase of revolutionary applications cr

Posted: December 21, 2023Read more »

In a surprising twist at the 2023 Ballon d'Or Ceremony in Paris, Adidas presented soccer legend Lionel Messi with a unique gift – a pair of custom-made shoes housed in a specially crafted 3D-printed shoebox. The innovative packaging, resembling a dodecahedron soccer ball, was a collaborative effort between Adidas and 3D printing pioneers, WASP.

Adidas's quest for a distinctive packaging solution for Messi's 8th Ballon d'Or win led them to the doorstep of WASP. The challenge was intriguing – design a dodecahedron-shaped shoebox that not only mirrored a soccer ball but could also snugly hold a limited edition pair of shoes tailored for Messi. The unconventional shape made 3D printing the perfect choice for manufacturing this piece of art.

The manufacturing process unfolded in four key steps. The shoebox was div

Posted: November 01, 2022Read more »FUTURE IN THE MAKING

If there’s something the coronavirus pandemic has made abundantly clear, it is that digital education is more than just moving the classroom to Zoom. Granted, technology has saved the day in the face of “the greatest shake-up in education in a century”, but it has also highlighted startling digital divides. Not only in terms of school and student access to digital tools but also in terms of opportunity to embed them in learning and teaching practices in meaningful ways, a recent paper has found.

Online educations worked much better where teachers had greater agency and were used to project-based teaching. Sadly, students in more traditional educational systems did worse, pointed out the OECD’s Andreas Schleicher among the key pandemic lessons learned at the first-ever T4 global teachers’ online conference. The time is now to realign teaching materials and adopt new methodologies to equip today’s youth with the skills they'll need to succeed in their di

Posted: October 28, 2022Read more »BRING LEARNING ALIVE WITH 3D PRINTING

When the first wave of the coronavirus pandemic hit, 3D printing proved a lifesaver in shortening production chains and providing much-needed medical supplies, like nasopharyngeal swabs and protective face shields, which had quickly become in short supply. Whether or not this momentum carries over post-pandemic is uncertain. The technology has the potential to revolutionize several areas of production where customization is key, from prosthetics to running shoes. Just how to make this transformation a reality, however, is a question organizations of all sizes and industries still grapple with.

Schools are no exception. 3D printers have been popping up in classrooms across the globe for years, but teachers often have a hard time figuring out what to do with them – let alone how to use the technology to prepare children for future jobs and teach indispensable skills. A global survey into the adoption of 3D printing in educational s

Posted: October 13, 2022Read more »"The machine is so easy to set up and use. I previously had a Glowforge which was very user-friendly (but very unreliable, as it broke 5 times in 7 months. So, on my 5th replacement I received a refund!) so I was worried I would find the transition hard as the Flux is a lot bigger and feels more "industrial". The machine is very well built, and sturdy compared to my previous laser, so I am very confident in having this machine support my business!"

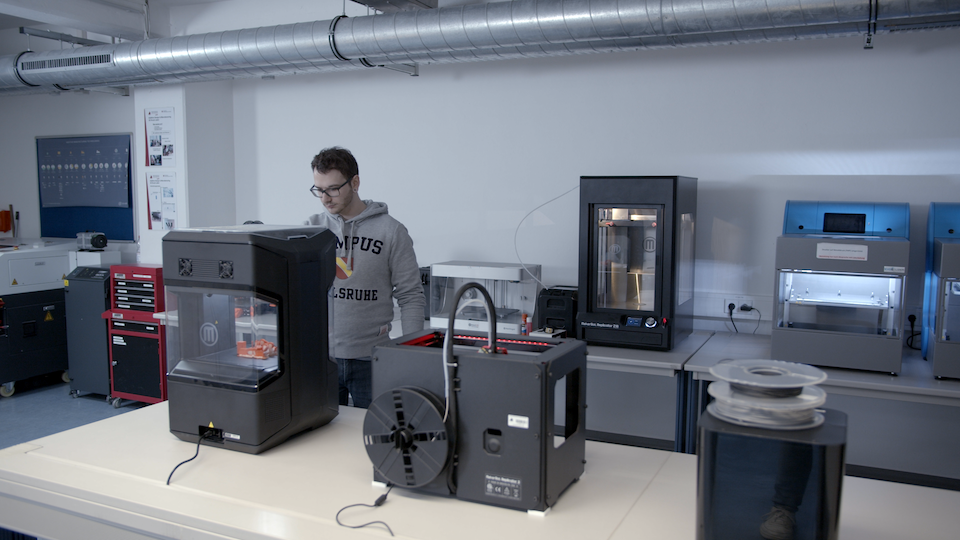

Posted: August 25, 2022Read more »Karlsruhe University of Applied Sciences is a prestigious 140+ year-old university delivering advanced engineering and technical training to students entering the workforce. Students utilize METHOD X for a range of applications, from research and development to industry thesis projects.

Prof. Dr Finsterwalder teaches the Additive Design and Manufacturing courses, where students are taught the foundations of generative design and additive manufacturing on both a theoretical and physical level.

“I believe that 3D printing is a valuable problem-solving tool and key competency for the future workforce. It was important to integrate this technology into our courses to give students a chance to use equipment that is currently being used within the design and manufacturing companies today,” said Prof. Dr Florian Finsterwalder.

The courses teach students how to conceptualize, design, and transform ideas into tangible objects they can physically manipulate. Stu

Posted: April 12, 2022Read more »

Daemon3D Print features in a blog on Manufacturing Tomorrow, read a snippet here or fill out the form below to read the full article!

'MakerBot, a Stratasys company initially set out in 2009 to become one of the first companies offering 3D printers that were affordable and available for all. The global 3D printer market has since only grown and was valued at US$12.6 billion in 2020. Rollem have used MakerBot 3D printers for a number of years but with the industry ever developing they were looking to upgrade.

Once Rollems Managing Director Stuart Murphy had decided that a 3D printer would be able to solve their issues, it was time for the much longer process of deciding which one. To answer that question Stuart would need to seek technical advice and support to ensure that he found the right printer for his requirements. Nicola Stokes, director at Daemon3D Print, and Stuart have known each other for 20 years, and they had caught up at a trade show where

Posted: February 09, 2022How Forever Rings uses Their FLUX Laser Cutter to Treasure Your Loved Ones That Have Been Lost

Read more »Forever Rings founded by Neil Slack creates rings and pendants to treasure your lost loved ones by combining their ashes with metal jewellery. Read below to find out more about how he creates his work and how he uses his FLUX laser cutter to achieve the final results.

Forever rings produce rings, necklaces, and pendants. The jewellery is fused or filled with cremation ash to give you a unique cherished memorial to a dearly beloved relative, loved one, or a fondly missed pet.

There are many different types of rings with different designs to choose from. The ring itself can be made from solid silver, damascus steel, tungsten carbide, titanium, or stainless steel. You can then choose an opal inlay or a dichrolam inlay in many different colours to make your ring even more special.

Posted: October 28, 2021Read more »

The new Method X & Labs Extruder Bundle means that with any MakerBot Method X or Method X Carbon Fibre 3D Printer, you can get a MakerBot Labs Extruder for FREE!.

The MakerBot METHOD X 3D Printer is one of the most intelligent 3D printers on the market combining industry expertise and technologies from Stratasys. Produce dimensionally accurate end-use parts (not just prototypes) that fit on the first try regardless of their complexity and can go from print to immediate use. And combined with the LABS Experimental Extruder

Method X Materials

The Method X can print with ABS, ASA, PC-ABS, and PC-ABS FR. ABS is MakerBot's toughest material, found in many common products such as LEGOS, computer keys, power-tool housings, and automotive parts. Because MakerBot's ABS doesn't have any of the extra additives added to it like most desktop ABS filaments do, It is capable of withstanding 15°C higher temperatures, is 26% more rigid and 12% stronger. And now the